Online type gas detector can be used in 24 hours continuous online monitoring of field gas concentration, 1.7-inch high-definition color screen will be used for the display of the field concentration, with field sound & light alarm (optional) when exceeding the standard, and remote signal transmission. The gas sensors of internationally known brands are adopted, and the main detection principles include: the gas sensors under the principle of electrochemical, infrared, catalytic combustion, thermal conductivity,PID photoionization, and so on. Is suitable for detecting the concentrations of gases in the atmosphere environment in the pipeline or confined space; and the purity of the gas leakage and various high concentration single gases with the background gas as nitrogen gas or oxygen gas. The types for detection are more than 500 types. Strong, durable and explosionproof shell is suitable for the use at a variety of hazardous places and harsh industrial environments, is widely used in the industries such as petroleum, chemical, metallurgy,refining,gas transmission and distribution, biochemical and pharmaceutical, and so on.

Model Click to consult

|

•Units can be switched freely |

•Diversified communication methods |

|

•Infrared remote control |

•Rich human-machine interface |

|

•Data recovery function; in case of mis-operation, it is possible to select partial or full recovery |

|

|

•It is possible to set whether to display the maximum value, minimum value or not |

|

|

•Multiple alarm modes, and multi-directional and three-dimensional indication alarm states |

|

|

•Multiple alarm mode settings: low alarm, high alarm, interval alarm, and weighted average alarm |

|

|

•Mis-operation recognition function: automatic recognition and prevention of the concentration calibration mis-operation, which is possible to avoid the poor performance that may be caused by human factors. |

|

|

•Zero-point automatic tracking; long-term use will not be affected by the zero drif |

|

|

•Multi-level calibration for target points, can ensure the linearity and accuracy of the measurements |

|

|

•Chinese or English interfaces can be selected. |

|

|

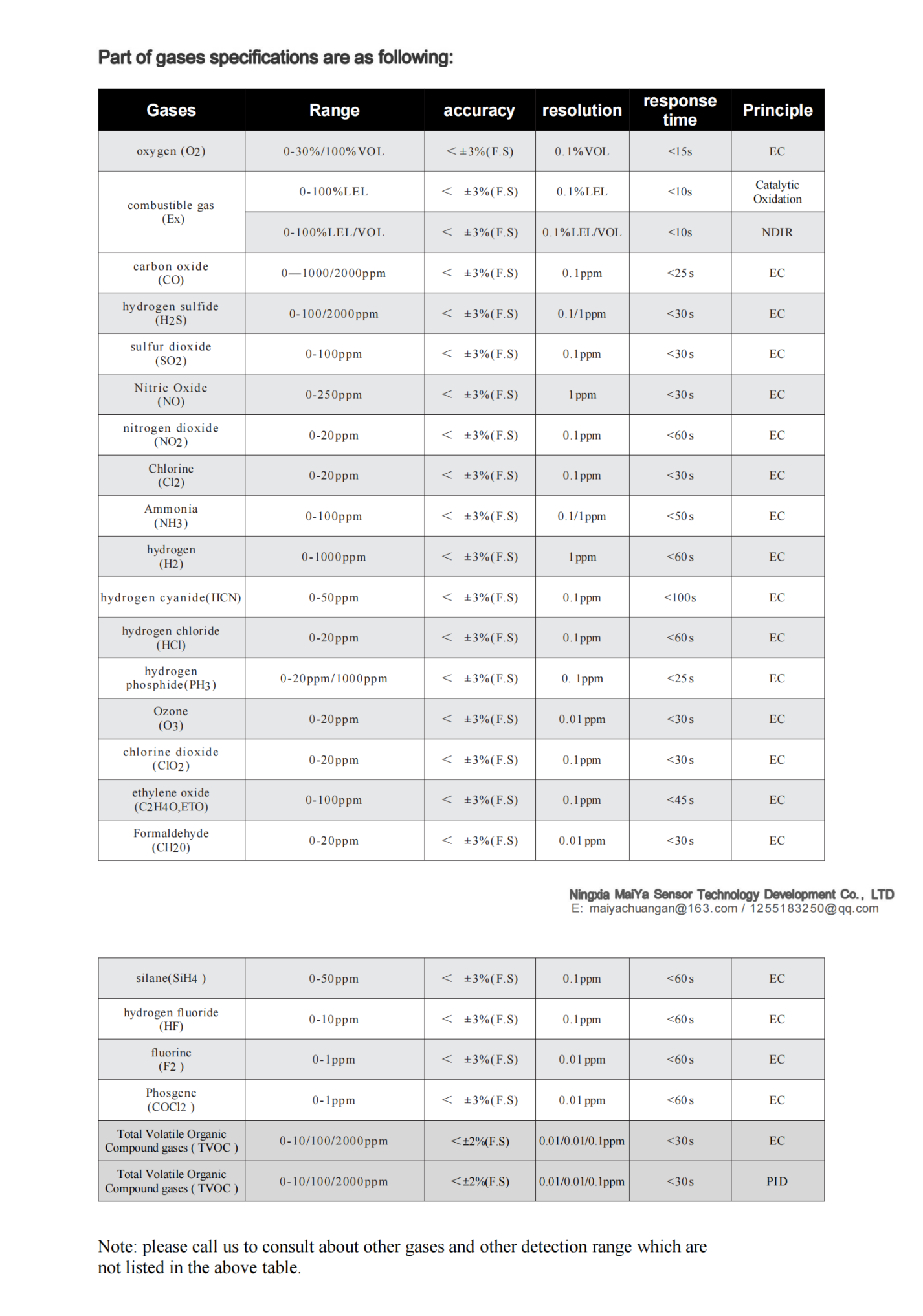

Gasestobe |

Toxic gases, oxygen gas, carbon dioxide, inflammable and explosivegases, TVOC, and so on. |

||||

|

Application |

All the cases which requires the fixed installation, and online detection of gas concentrations such as petroleum, chemical, pharmaceutical, environmental protection, combustion gas distribution, warehousing, smoke gas analysis, air governance, and so on. |

||||

|

Detection |

0~1,10,100,1000,5000,50000,100000ppm,200 mg/L,100%LEL,20%,50%,100%Vol,can be selected;and other ranges can be customized. |

||||

|

Resolution |

0.01ppm or 0.001ppm (0 ~ 10 ppm); 0.01ppm (0 ~ 100 ppm), 0.1ppm (0 ~ 1000 ppm), 1ppm (0 ~ 10000 ppm or more),0.01 mg/l (0 ~ 200 mg/l), 0.1% LEL, 0.01%, 0.001% Vol |

||||

|

Detectionprinciple |

Electrochemical, catalytic combustion, infrared, thermal conductivity,PID photoionization, and so on, depending on the type of gas, range,field environment and user demand |

||||

|

Sensorservice |

Electrochemical principle:2~3 years;Oxygen gas:2 years or 6 yearscan be selected; infrared principle:5~10years; catalytic combustion:3 years; thermal conductivity:5 years. |

||||

|

Detectionaccuracy |

≤±3%F.S(Higher accuracy level can be customized) |

||||

|

Linearity |

≤±2% |

Repeatability |

≤±2% |

Uncertainty |

≤±2% |

|

Responsetime |

T90≤20 seconds |

Recoverytime |

≤30 seconds |

||

|

Signaloutput |

Bus system RS485(RTU),three(four)wire system 4~20mA,optional configuration:0~20mA,1~5V,0~5V,0~10V,wirelesstransmission, network transmission, and SMS alarms. |

||||

|

Workingenvironment |

Temperature:-40℃~+70℃,humidity:≤10~95% RH(regular)non-condensing case It should be customized in the case of use in the condensing case, orthe use environment should be specified at the time of ordering |

||||

|

Displaymethod |

1.7-inch high-definition color screen for field display, it is possibleto select no field display, or the optional configuration of MIC2000controller for remote display, control, and alarm |

||||

|

Workingvoltage |

12~36V DC direct current, the standard power supply for a singleequipment is 24V, DC stabilized voltage switching power supply of1A or greater than 1A |

||||

|

Power supply |

The switching power supply of24V,2.1A is possible to drive 40 unitsof toxic gas detector, or 15 units of flammable, infrared gas detector |

|

Working method |

Fixed type installation, online detection, diffusion type measurement;and it is possible to select the measurement of pipeline type, flowthrough type, and pump-suction type. |

|

Installation |

Pipeline type, and wall mounting type. The working pressure of thepipeline type is±30% of atmospheric pressure,and when exceededthis range, it is necessary for the depressurization treatment. |

|

Alarm method |

The default option is 1-way, and it is possible to select 2-way passivecontact(dry contact) output, level III alarm, and the alarm point canbe set. Field sound & light alarm (optional configuration). |

|

Connecting |

Adopted 4~20mA three-core shielding cable, adopted four-core forRS485, when the distance exceeded 100 meters, the single wire diameter≥1.5mm; and the shielding layer will be connected to the earth |

|

Protection |

IP65 |

|

Explosion-proof type |

Explosion suppression type |

|

Explosion-proof |

Ex d IC T6 Gb |

|

Exterior dimensions |

230×152×90mm(L×H×W) |

|

Weight |

1.8Kg |

|

Standard accessories |

Manual, qualification certificate, warranty card, outer packaging box |

|

Optional items |

Integrated sound & light alarming device, split-type sound & lightalarming device, 24V DC stabilized voltage power supply,accessory for connection with computer for monitoring: free upper-level host software, RS485/RS232 converter, |

|

Wireless transmission |

Optional function is possible to transfer data wirelessly to the cellphone, remote monitoring center, monitoring computers and othermonitoring equipment, which will utilize the upper-level host to realize the functions of data analysis, storage, printing or the like on thecomputer |

|

Pretreatment |

Optional configuration: room temperature and high humidity pretreatment system, high temperature and high humidity pretreatmentsystem, high temperature and high humidity and high dust pretreatment system |

|

Installation |

Optional configuration: wall mounting bracket, mounting clips forfixation on the pipes(1/2”,3/4”pipe),stainless steel threaded welding seat or flange to be installed on the |

TEL:18995278133ADD:Block A, Yinchuan Zhongguancun Innovation Center, Xingzhou Street, Xixia District, Yinchuan, Ningxia

Copyright©2025 Ningxia Maiya Sensor Technology Development Co., Ltd

宁ICP备2022001619号-1